LC Provolt Filter for sinusoidal output in Frequency Inverters

.png)

Frequency inverters for three-phase motors have the basic function of varying the frequency applied to the motor for drive with controlled speed and starting. The variable frequency control system's operating principle is the use of PWM modulation, which is a high frequency carrier frequency that can vary in most applications between 2kHz and 16kHz.

This PWM carrier frequency synthesizes the sine waveform through the high frequency pulses. In operation, the motor normally absorbs this high frequency and the controls result in a small heating effect and damage to the wiring and motor bearing, but limited to a distance of approximately 20 meters between the motor and the inverter.

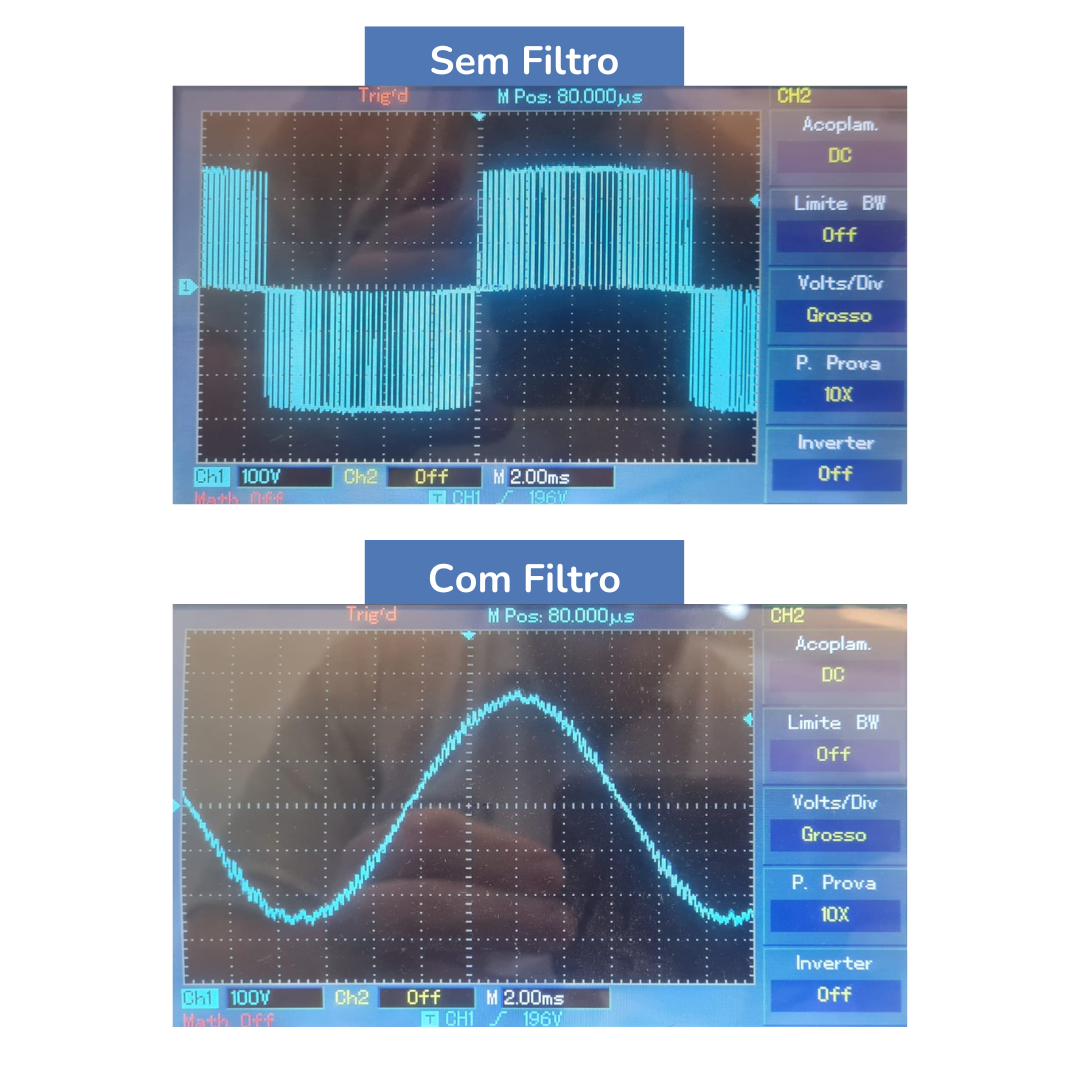

Lengths above 20 meters increase the harmful effect of high frequency on the motor and for this purpose the use of inductive filters, “L” filter, is necessary to attenuate the harmful effects of high frequency. For an even better result and even more effective reduction, an “LC Provolt” filter is even more effective, since the voltage output eliminates high-frequency carriers from the modulation and the resulting filter is a pure sine wave, similar to that of the network. commercial. With the addition of the “LC Provolt” filter, it is possible to drive motors at a long distance from the inverter without damaging the motor, as seen in the comparative figures below.